|

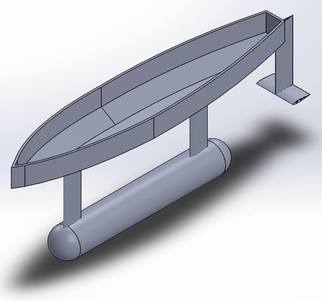

Wow! The competition is just two months away! Eager to see how our boat looks like? Let's trace SwinSurfer's footsteps. More updates will be posted soon.

0 Comments

We, SwinSurfers are one of the 26 teams from 12 countries that signed up to compete in the 3rd #Hydrocontest!

Τhe year ahead presents you new hοrizons, fresh οpportunities and new hοpes. Seize the opportunities and make the most οf the Chinese Νew Year of Τhe Monkey.

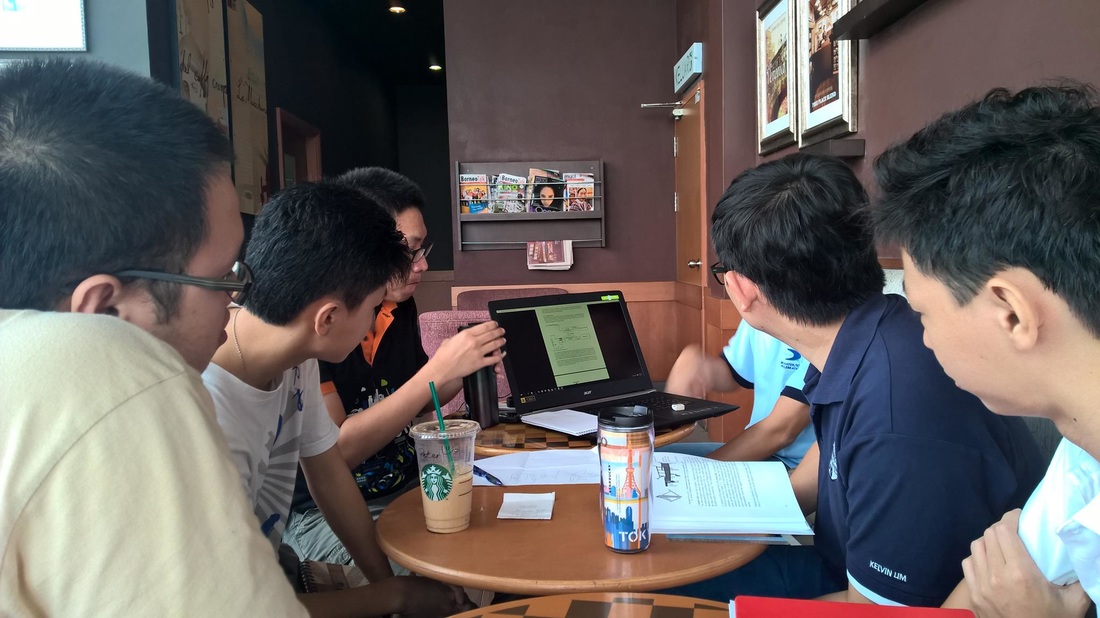

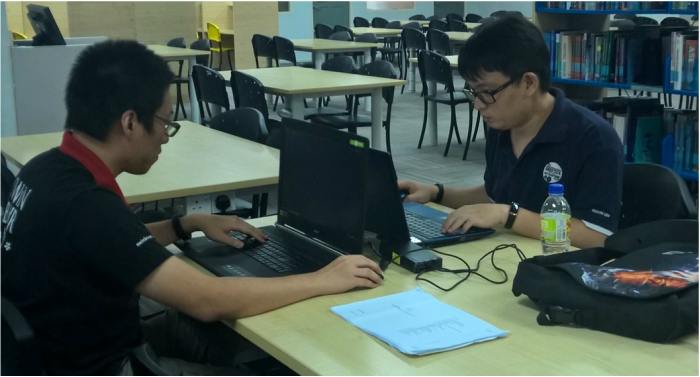

Wow! The competition is just one month away! We are now perfecting the boat. Sorry for having no updates for the past few weeks! As of now, we had the metal frame in place to hold the boat together, and had tested the boat for seaworthiness.... oops, I mean lake-worthiness..... haha... Here's the boat with some metal frame attached to stabilize the structure. Each connections are bolted tightly to secure the hulls to the main structure. Waterproofing was done on each connection point to prevent the ingress of water into the hull of our boat. The metal frame is not merely bolted to the surface of the hull. It actually goes into the hull and act as a support for the boat. As a result, we have a stable boat that is able to withstand the load of at least 3 grown man!!

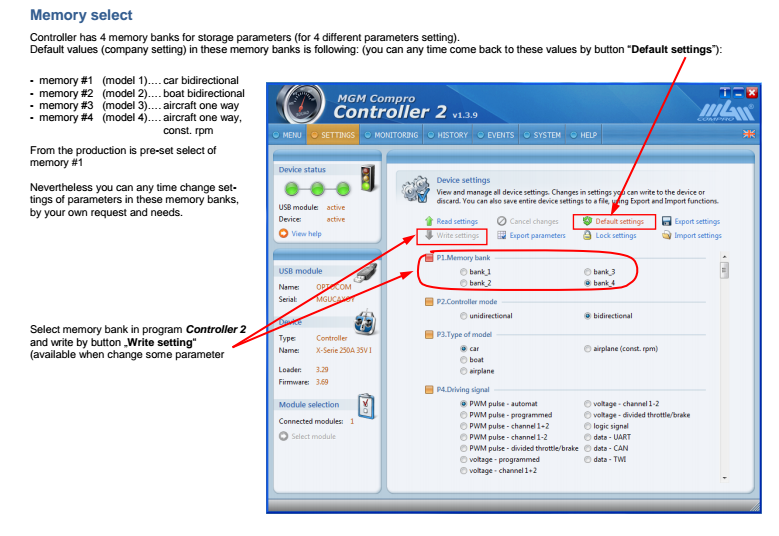

The holes on the hulls are designed so that weights can be placed inside the hull for stability. While the built team is doing this, the electrical team is still figuring our the best electrical configuration for optimized speed and safety. Hey guys, sorry for the late updates, last week, our controller board FINALLY arrived! Talk about rushed development cycle! We have to figure our the operation of the board ASAP! It turns out, this board is so expensive for a number of reasons. First of all, it supports different types of input, be it potentiometer, PWM, Serial, or even TTL logic. This makes it really versatile for different purposes. The manufacturer advertises it as being able to control planes, boats as well as cars. To design the control system, we basically configure the board to receive PWM input from the RF receiver module. Normally, in an RC car, the PWM signals will be fed into an Electronic Speed Controller (ESC), which will in turn, control the main motor of the RC car. For our case, this board is our ESC, and the signal from the RC module will be fed directly into the board. Programming the board is relatively straightforward. There are several preset values for the boat which will be available for us to load into the controller. The settings are defined as memory 'banks', which contains settings optimized for various applications. For our case, we are modifying the settings with Bank_2 as our starting point.

More updates will be posted once the device is ready for test. |

SwinsurfersGet the latest updates on build progress right here. Archives

May 2016

Categories |

RSS Feed

RSS Feed